The world is rapidly shifting towards electric vehicles (EVs). As this trend grows, the need for efficient charging solutions becomes crucial. An AC Charging Pile Manufacturer plays a vital role in this transformation. They design and produce charging piles that power EVs safely and effectively.

These manufacturers focus on quality and performance. However, some products may not meet all user expectations. Moreover, the variety of charging options can be overwhelming. A well-designed charging station enhances user experience, but not all manufacturers prioritize this. It's essential for manufacturers to listen to customer feedback and innovate continuously.

The future of transportation depends on reliable and accessible charging infrastructure. AC Charging Pile Manufacturers must adapt to evolving technologies. This journey is not without challenges. Balancing cost, quality, and technology is a complex task. Yet, it's critical for sustainable growth in the EV market. Customers demand more, and manufacturers must rise to the occasion.

An AC charging pile is a vital component in the electric vehicle (EV) ecosystem. It provides a standardized way to charge EVs using alternating current. Many public places, such as parking lots and shopping centers, are equipped with these charging piles. They are designed to connect to the vehicle's onboard charger, converting AC power to DC, which is stored in the car's battery.

The role of an AC charging pile manufacturer is crucial. These manufacturers must ensure their products meet safety and performance standards. They design the charging piles to withstand various environmental conditions. However, there can be challenges, such as compatibility issues with different vehicle models. This can lead to user frustration when charging stations do not work with certain EVs.

Moreover, installation of AC charging piles requires careful planning. Site assessments are essential to determine optimal locations. Some areas may face space constraints or electrical supply issues. Manufacturers must navigate these challenges to deliver reliable charging solutions. The growth of electric mobility relies on functional and accessible charging infrastructure. Addressing these needs is an ongoing challenge in the industry.

| Feature | Description |

|---|---|

| Power Output | Typically ranges from 3.7 kW to 43 kW, depending on the charger type and usage. |

| Charging Standards | Supports various standards including Type 1, Type 2, and CCS for compatibility. |

| Installation Locations | Can be installed in public charging stations, residential areas, and workplaces. |

| Safety Features | Equipped with overcurrent, short-circuit, and ground fault protection mechanisms. |

| User Interface | Many include touchscreens, mobile app connectivity, and support for multiple languages. |

| Maintenance | Regular inspections and software updates are essential for optimal performance. |

| Market Trends | Growing demand for electric vehicles is increasing the need for more AC charging solutions. |

The role of AC charging pile manufacturers is crucial in today’s electric vehicle landscape. These manufacturers design and produce the equipment needed to charge electric vehicles safely and efficiently. This is not just about production; it involves ensuring reliability and safety. The technology must meet various standards for performance and compatibility.

Without these manufacturers, the infrastructure for electric vehicles would falter. More cars are going electric, yet charging stations are still sparse in many areas. It's frustrating for drivers. Some manufacturers struggle with supply chain issues. This can delay the rollout of new charging stations. Moreover, not all manufacturers prioritize sustainability. This can have long-term effects on the environment.

Innovation is key in this industry. Manufacturers are exploring faster charging options and smarter technology. However, there’s pressure to keep costs low. The balance between affordability and quality is tricky. Consumers want effective solutions, but they also want value. It's an ongoing challenge that requires reflection and adaptation. Manufacturers must listen to feedback to improve their products continuously.

AC charging pile manufacturers play a crucial role in the electric vehicle ecosystem. They are responsible for designing and producing charging stations that power electric cars. These manufacturers ensure the stations meet safety standards and efficiency requirements. They must consider voltage levels and charging speeds. Many manufacturers also focus on user-friendly features, like touch screens and mobile app connections.

One essential function is research and development. These manufacturers constantly innovate to enhance charging technology. Challenges remain, such as how to reduce costs while improving performance. Sustainability is another concern, as some materials used may not be eco-friendly. Additionally, there’s the matter of compatibility with different electric vehicle models.

Market demand pushes manufacturers to adapt quickly. They must remain flexible to cater to evolving customer needs. While they strive for excellence, the quest for perfect solutions often leads to learning from mistakes. This ongoing journey of improvement shapes the future of electric mobility. Every step taken has a profound impact on the industry.

This chart illustrates the key functions of AC charging pile manufacturers based on the estimated work output across various dimensions.

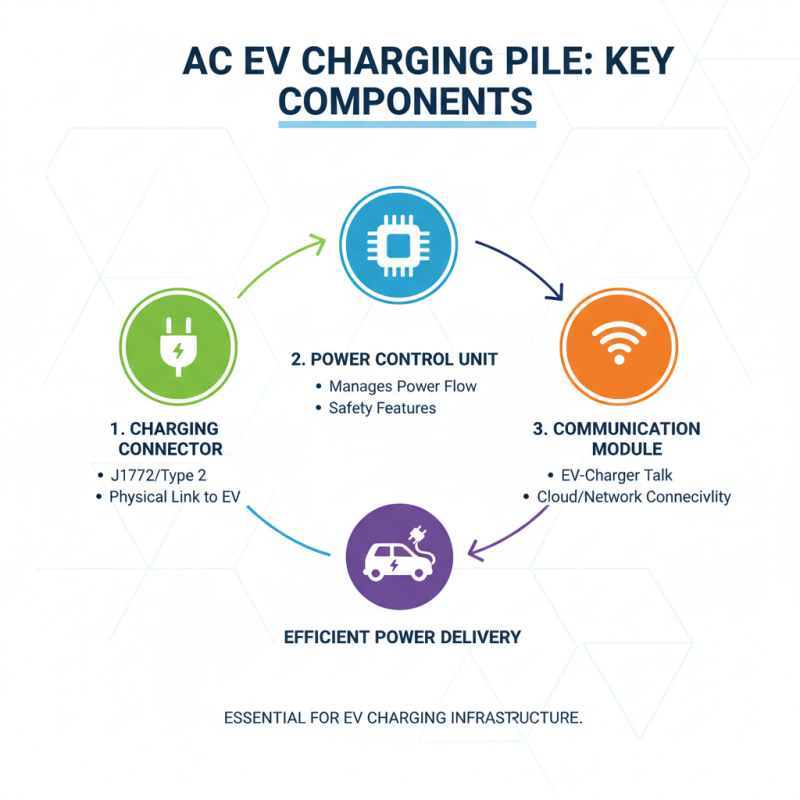

AC charging piles play a crucial role in the electric vehicle ecosystem. They consist of several key components that work together to deliver power. The main parts include the charging connector, power control unit, and communication module. Each element is essential for efficient operation.

The charging connector ensures a secure connection to the vehicle. It must meet specific standards for safety and performance. The power control unit regulates the flow of electricity. It helps prevent overheating and ensures a smooth charging experience. Meanwhile, the communication module allows the charging pile to interact with the vehicle. It shares vital data like charge status and battery health.

Technologies used in AC charging piles continue to evolve. New features enhance user convenience and safety. However, challenges remain. Compatibility issues can arise between different vehicles and charging stations. Not all piles support fast charging. This inconsistency may frustrate users seeking quick solutions. It is an area needing improvement. The future of AC charging piles relies on innovation and standardization.

The future of AC charging pile manufacturing is evolving rapidly. As electric vehicles gain popularity, the demand for efficient charging solutions increases. Manufacturers are exploring innovative materials and technologies.

Lightweight components can enhance portability. This trend may drive down production costs while improving efficiency.

Sustainability remains a key focus. More manufacturers are turning to eco-friendly materials. The carbon footprint of production is under scrutiny. Balancing performance with environmental responsibility is crucial. This shift could lead to higher initial costs but long-term savings.

Moreover, smart charging technologies are gaining traction. Integrating IoT features into charging piles can optimize energy use. Real-time monitoring may help in identifying issues promptly. However, this requires robust cybersecurity measures. Ensuring user safety is non-negotiable. These challenges need careful consideration in future designs. Manufacturers must adapt to changing technology while addressing these emerging complexities.